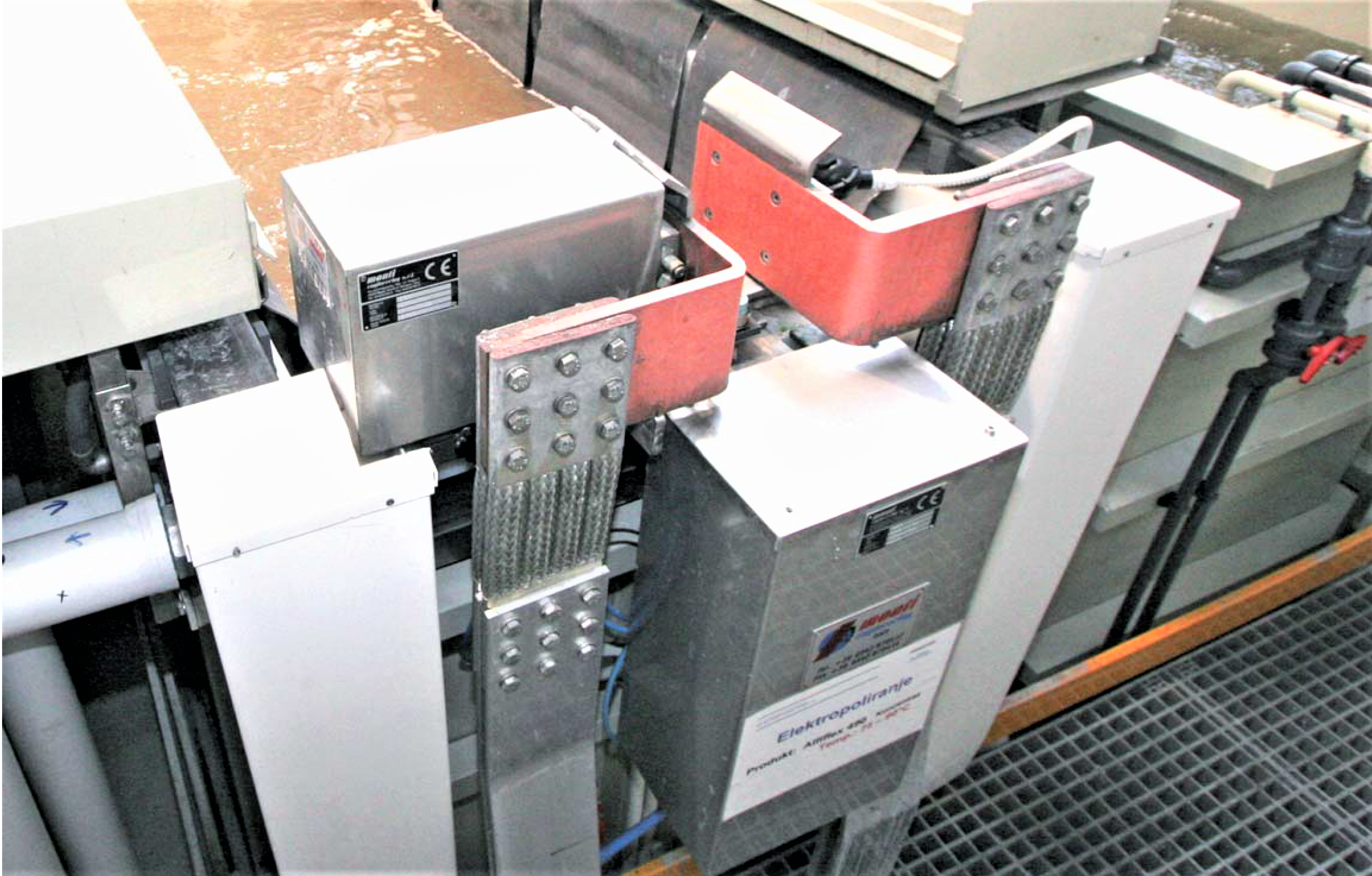

pneumatic electric contacts

A special copper electric contact, driven by a double chamber (tandem) pneumatic cylinder is used to supply current to the anodic bar.

This practical system reduces the power loss, for the great pressure created by the cylinder is such as to keep an optimal contact between the anodic bar surfaces and the cylinder contact surfaces.

According to the requirements, the system can use a simple or double contact, i.e. it can feed one or two anodic bars at the same time.

The cylinder can work with manual drive or it can work automatically with electro-valves and security sensors.

For high currents the electric contact is equipped with cooling radiators with water circulation. The contacts water cooling avoids dissipating energy by overheating of the surfaces, due to the current passage.

The cylinder is supplied complete with stainless steel support to be easily fixed onto the edge of the tank and of the accessories for air connection.

In some immersion treatment processes (like electro-brightening and electro-colouring), in addition to bringing the current to the anodic bar, it is also necessary to have the mechanical movement of the pieces in order to obtain a surface finish free from defects.

The electro-pneumatic contacts mounted on mover devices are particularly suitable for these processes.

The unit is supplied complete with a pneumatic electric contact, a horizontal movement system which moves the workpiece holder bar with an alternative motion and a roller device for resting and sliding the workpiece holder bar on the side opposite the control.